Hoʻohālikelike kēia alakaʻi piha i ka 25 mau mea maʻamau i hoʻohana ʻia i ka mīkini CNC a kōkua iā ʻoe e koho i ka mea kūpono no kāu noi.

Hiki i ka mīkini CNC ke hana i nā ʻāpana mai kahi kokoke i nā metala a i ʻole ka plastic.ʻO kēia ka hihia, aia ka nui o nā mea i loaʻa no nā ʻāpana i hana ʻia ma o CNC milling a huli.He mea paʻakikī ke koho ʻana i ka mea kūpono no kāu noi, a he mea koʻikoʻi ka hoʻomaopopo ʻana i nā pono a me ka hoʻohana maikaʻi ʻana o kēlā me kēia mea i loaʻa.

Ma kēiaʻatikala, hoʻohālikelike mākou i nā mea CNC maʻamau, ma keʻano o ka mechanical a me ka thermal properties, ke kumukūʻai a me nā mea maʻamau (a me ka maikaʻi).

Pehea ʻoe e koho ai i nā mea CNC pono?

Ke hoʻolālā nei ʻoe i kahi ʻāpana e hana ʻia i ka mīkini CNC, pono ke koho ʻana i nā mea pono.Eia nā ʻanuʻu kumu a mākou e paipai nei e koho i nā mea pono no kāu mau ʻāpana maʻamau.

E wehewehe i nā mea e pono ai: Hiki i kēia mau mea ke komo i nā koi mechanical, thermal a i ʻole nā mea waiwai ʻē aʻe, a me ke kumukūʻai a me ka hoʻopau ʻana i ka ʻili.E noʻonoʻo pehea ʻoe e hoʻohana ai i kāu mau ʻāpana a me ke ʻano o ke kaiapuni e noho ai lākou.

E ʻike i nā mea moho: E hoʻopaʻa i kekahi mau mea moho e hoʻokō i nā mea a pau (a i ʻole ka hapa nui) o kāu mau koi hoʻolālā.

E koho i ka mea kūpono loa: Pono maʻamau ka kuʻikahi ma waena o ʻelua a ʻoi aʻe paha o nā koi hoʻolālā (no ka laʻana, ka hana mechanical a me ke kumukūʻai).

Ma kēia ʻatikala, e kālele mākou i ka ʻanuʻu ʻelua.Me ka hoʻohana ʻana i ka ʻike i hōʻike ʻia ma lalo nei, hiki iā ʻoe ke ʻike i nā mea i kūpono loa i kāu noi, ʻoiai e mālama ana i kāu papahana ma ke kālā.

He aha nā kuhikuhi a Hubs no ke koho ʻana i nā mea no CNC?

Ma nā papa ma lalo nei, hōʻuluʻulu mākou i nā hiʻohiʻona kūpono o nā mea CNC maʻamau, i hōʻiliʻili ʻia ma ka nānā ʻana i nā ʻikepili i hāʻawi ʻia e nā mea hana.Hoʻokaʻawale mākou i nā metala a me nā plastics i ʻelua mau ʻāpana like ʻole.

Hoʻohana nui ʻia nā metala i nā noi e koi ai i ka ikaika kiʻekiʻe, ka paʻakikī a me ke kūpaʻa wela.ʻO nā plastik he mau mea māmā me ka nui o nā waiwai kino, hoʻohana pinepine ʻia no ko lākou kūpaʻa kemika a me ka hiki ke hoʻokaʻawale uila.

I kā mākou hoʻohālikelike ʻana i nā mea CNC, nānā mākou i ka ikaika mechanical (i hōʻike ʻia e like me ka tensile yield strength), machinability (ʻo ka maʻalahi o ka mīkini e pili ana i ke kumu kūʻai CNC), ke kumu kūʻai, ka paʻakikī (no nā metala) a me ke kūpaʻa wela (ka mea nui no nā plastic).

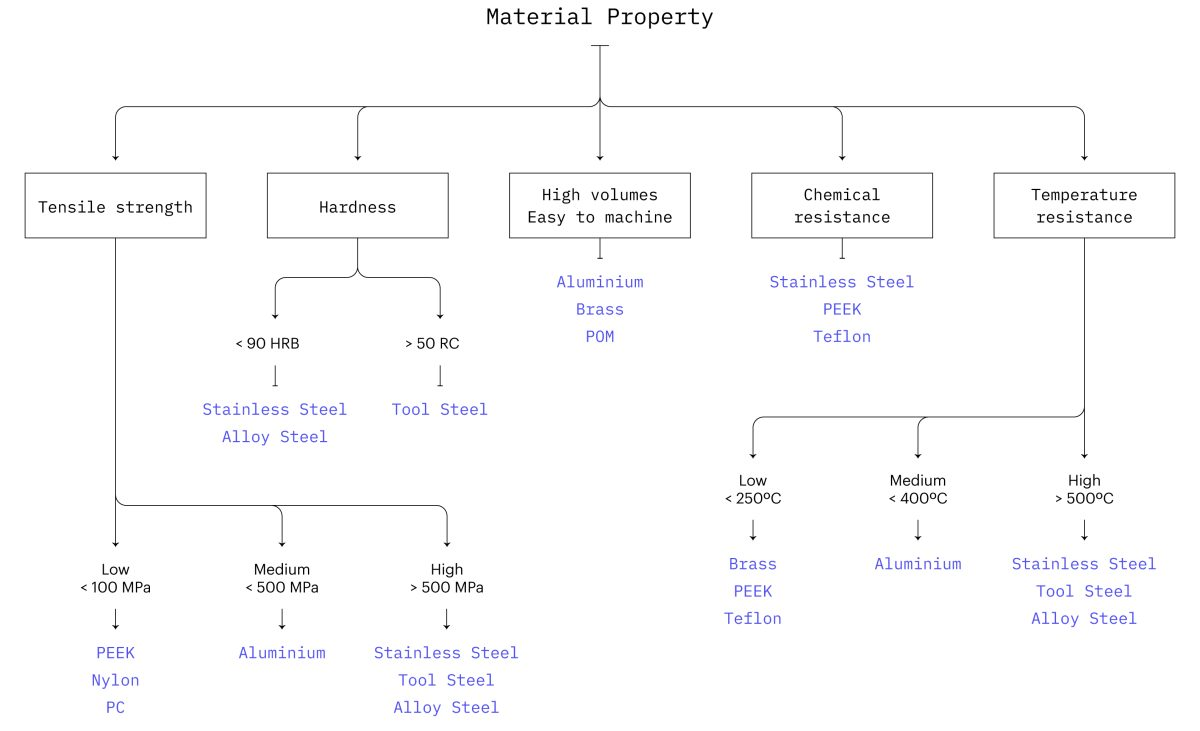

Eia kahi infographic hiki iā ʻoe ke hoʻohana ma ke ʻano he kuhikuhi wikiwiki e ʻike koke i nā mea CNC e kūpono i nā pono ʻenehana kikoʻī.

He aha ka alumini?ʻO ka paʻa paʻa, hoʻokele waiwai

ʻO kahi mea i hana ʻia me ka Aluminum 6061

Loaʻa i nā alumini alumini ka lākiō ikaika-a-kaumaha, kiʻekiʻe ka wela a me ka uila a me ka pale kūlohelohe i ka corrosion.He maʻalahi lākou i ka mīkini a me ke kumu kūʻai i ka nui, hana pinepine iā lākou i ke koho ʻoi aku ka maikaʻi no ka hana ʻana i nā prototypes a me nā ʻano ʻāpana ʻē aʻe.

ʻOiai ʻoi aku ka liʻiliʻi o ka ikaika a me ka paʻakikī o nā alumini alumini ma mua o nā kila, akā hiki ke anodized, e hana ana i kahi paʻa paʻa, pale pale ma ko lākou ʻili.

E hoʻokaʻawale i nā ʻano like ʻole o nā alumini alumini.

❖ ʻO ka Aluminum 6061 ka mea maʻamau, hoʻohana maʻamau i ka alumini alumini, me ka ratio ikaika-a-kaumaha maikaʻi a me ka machinability maikaʻi loa.

❖ Loaʻa i ka Aluminum 6082 ka haku mele a me nā waiwai waiwai me 6061. Ua hoʻohana maʻamau ia ma ʻEulopa (e like me ka hoʻokō ʻana i nā Kūlana Pelekane).

❖ ʻO ka Aluminum 7075 ka huila i hoʻohana pinepine ʻia i nā noi aerospace kahi mea koʻikoʻi ka hoʻemi kaumaha.Loaʻa iā ia nā waiwai luhi maikaʻi a hiki ke mālama ʻia ka wela i ka ikaika kiʻekiʻe a me ka paʻakikī, e hoʻohālikelike ʻia me nā kila.

❖ ʻOi aku ka ikaika o ka Aluminum 5083 ma mua o ka nui o nā alumini alumini ʻē aʻe a me ke kūpaʻa kūʻokoʻa i ka wai kai.ʻO kēia ka mea kūpono no ke kūkulu ʻana a me nā noi kai.He koho maikaʻi nō hoʻi ia no ka welding.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau o nā alumini alumini: 2.65-2.80 g/cm3

❖ Hiki ke anodized

❖ ʻAʻole-magnetic

He aha ke kila kila?ʻO ka hao ikaika a paʻa

ʻO kahi ʻāpana i hana ʻia mai ke kila kila 304

Loaʻa ka ikaika kiʻekiʻe, ka ductility kiʻekiʻe, ka ʻaʻahu maikaʻi a me ke kūpaʻa corrosion a hiki ke maʻalahi i ka welded, machined a poli.Ma muli o kā lākou haku mele ʻana, hiki iā lākou ke ʻano (mea nui) non-magnetic a i ʻole magnetic.

E hoʻokaʻawale i nā ʻano kila kuhili ʻole a mākou e hāʻawi ai ma ka paepae.

❖ ʻO ke kila kila 304 ka mea maʻamau maʻamau.Loaʻa iā ia nā waiwai mechanical maikaʻi a me ka machinability maikaʻi.He kū'ē i ka hapa nui o nā kūlana kaiapuni a me nā media corrosive.

❖ ʻO ke kila kila ʻole 316 kekahi mea hoʻoheheʻe kila maʻamau me nā ʻano mekini like me 304. ʻOi aku ka ʻoi aku o ka ʻino a me ke kūpaʻa kemika akā naʻe, ʻoi aku ka nui o ka wai paʻakai (e like me ka wai kai), no laila ʻoi aku ka maikaʻi no ka hana ʻana i nā kaiapuni ʻoi aku ka paʻakikī.

❖ ʻO ke kila kila 2205 Duplex ka ikaika kiʻekiʻe loa (ʻelua ʻelua o nā ʻāpana kila kila maʻamau) a me ke kūpaʻa maikaʻi loa i ka ʻino.Hoʻohana ʻia ia i nā kaiapuni koʻikoʻi, me nā noi he nui i ka ʻaila & Gas.

❖ He ʻoi aku ka paʻakikī o ke kila kila 303, akā haʻahaʻa ka pale ʻana i ka corrosion i hoʻohālikelike ʻia me 304. Ma muli o kona machinability maikaʻi loa, hoʻohana pinepine ʻia i nā noi kiʻekiʻe, e like me ka hana ʻana i nā nati a me nā bolts no ka aerospace.

❖ ʻO ke kila kila 17-4 (SAE grade 630) loaʻa nā waiwai mechanical e hoʻohālikelike ʻia me 304. Hiki ke hoʻopaʻakikī ʻia ka ua i kahi kiʻekiʻe kiʻekiʻe (e hoʻohālikelike ʻia me nā kila mea hana) a loaʻa iā ia ke kūpaʻa kemika maikaʻi loa, kūpono ia no nā noi kiʻekiʻe loa. e like me ka hana ʻana i nā ʻili no nā turbine makani.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 7.7-8.0 g/cm3

❖ Nā huila kila kuhiliʻole ʻole: 304, 316, 303

❖ Nā huila kila kuhiliʻole: 2205 Duplex, 17-4

He aha ke kila māmā?ʻO ka huila kumu nui

ʻO kahi ʻāpana i hana ʻia mai Mild Steel 1018

Nā kila māmāʻike ʻia ʻo ia he mau kila haʻahaʻa haʻahaʻa a loaʻa nā waiwai mechanical maikaʻi, ka machinability nui a me ka weldability maikaʻi.Ma muli o ke kumu kūʻai haʻahaʻa, hoʻohana nā mea hana iā lākou no nā noi kumu maʻamau, e like me jigs a me nā mea paʻa.Pilikia nā kila māmā i ka ʻino a me ka pōʻino kemika.

E hoʻokaʻawale kākou i nā ʻano kila māmā i loaʻa ma ka paepae.

❖ ʻO ke kila maʻemaʻe 1018 he mea hoʻohana maʻamau me ka machinability maikaʻi a me ka weldability a me ka paʻakikī, ikaika a me ka paʻakikī.ʻO ia ka mea maʻamau i hoʻohana pinepine ʻia.

❖ ʻO ke kila maʻemaʻe 1045 he kila kalapona maʻamau me ka maikaʻi o ka weldability, ka machinability maikaʻi a me ka ikaika kiʻekiʻe a me ke kūpaʻa hopena.

❖ ʻO ke kila haʻahaʻa ʻo A36 he kila hana maʻamau me ka weldability maikaʻi.He kūpono ia no nā ʻano hana ʻenehana a me ke kūkulu hale.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 7.8-7.9 g/cm3

❖ Mākēneki

He aha ke kila kila?ʻO ka mea ʻoi aku ka ʻoi aku o ka ʻoi aku ka ʻoi aku o ka ʻoi aku o ka paʻakikī, a me ka paʻa paʻa

He ʻāpana i hana ʻia mai ke kila kila

Loaʻa i nā kila Alloy kekahi mau mea hoʻohuihui ʻē aʻe me ke kalapona, ka hopena i ka hoʻomaikaʻi ʻana i ka paʻakikī, ka paʻakikī, ka luhi a me ka pale ʻana.E like me nā kila haʻahaʻa, hiki ke hoʻopaʻa ʻia nā kila kila i ka corrosion a me nā hoʻouka ʻana mai nā kemika.

❖ Loaʻa i ke kila kila 4140 maikaʻi nā waiwai mīkini holoʻokoʻa, me ka ikaika a me ka paʻakikī.He kūpono kēia alloy no nā ʻoihana ʻoihana he nui akā ʻaʻole ʻōlelo ʻia no ka wili.

❖ Hiki ke hoʻohana ʻia ke kila kila 4340 i ka wela i nā pae kiʻekiʻe o ka ikaika a me ka paʻakikī, ʻoiai e mālama ana i kona ʻoʻoleʻa maikaʻi, ʻaʻahu i ke kūpaʻa a me ka ikaika luhi.Hiki ke weldable kēia huila.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 7.8-7.9 g/cm3

❖ Mākēneki

He aha ke kila mea hana?ʻO ka huila paʻa paʻakikī a kūpaʻa

He ʻāpana i hana ʻia mai ke kila mea hana

Nā kila kilahe mau mea metala me ka paʻakikī kiʻekiʻe loa, ʻoʻoleʻa, abrasion a me ke kūpaʻa wela, inā lōʻihi lākou.lapaʻau wela.Hoʻohana ʻia lākou e hana i nā mea hana hana (no laila ka inoa) e like me ka make, nā peʻa a me nā mold.

E wāwahi kākou i nā kila mea hana a mākou e hāʻawi nei ma Hubs.

❖ ʻO ke kila kila D2 ka mea hoʻopaʻa paʻa i ka wela o 425°C.Hoʻohana maʻamau ia e hana i nā mea hana ʻoki a make.

❖ ʻO ke kila kila A2 he kila mea hana maʻamau i hoʻopaʻa ʻia i ka ea me ka paʻakikī maikaʻi a me ke kūpaʻa maikaʻi loa i nā wela kiʻekiʻe.Hoʻohana maʻamau ia no ka hana ʻana i nā make molding injection.

❖ ʻO ke kila kila ʻO1 kahi huila i hoʻopaʻa ʻia i ka ʻaila me ka paʻakikī kiʻekiʻe o 65 HRC.Hoʻohana maʻamau ia no nā pahi a me nā mea hana ʻoki.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 7.8 g/cm3

❖ Oolea maʻamau: 45-65 HRC

He aha ke keleawe?ʻO ka conductive & cosmetic alloy

He hapa keleawe C36000

keleawehe metala metala me ka machinability maikaʻi a me ka maikaʻi o ka uila conductivity, i mea kūpono no nā noi e koi ana i ka haʻahaʻa friction.E ʻike pinepine ʻoe i nā ʻāpana keleawe hoʻonaninani i hoʻohana ʻia no nā kumu hoʻolālā (nā kikoʻī gula).

Eia ke keleawe a mākou e hāʻawi nei ma Hubs.

❖ ʻO Brass C36000 kahi mea me ka ikaika tensile kiʻekiʻe a me ka pale ʻana i ka corrosion kūlohelohe.ʻO ia kekahi o nā mea machinable maʻalahi loa, no laila hoʻohana pinepine ʻia no nā noi kiʻekiʻe.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 8.4-8.7 g/cm3

❖ ʻAʻole-magnetic

He aha ka ABS?ʻO ka thermoplastic prototyping

ʻO kahi ʻāpana i hana ʻia mai ABS

ABSʻO ia kekahi o nā mea thermoplastic maʻamau e hāʻawi ana i nā waiwai mechanical maikaʻi, ka ikaika hopena maikaʻi loa, ke kūpaʻa wela kiʻekiʻe a me ka machinability maikaʻi.

He haʻahaʻa haʻahaʻa ka ABS, kūpono ia no nā noi māmā.Hoʻohana pinepine ʻia nā ʻāpana ABS mīkini CNC e like me nā prototypes ma mua o ka hana nui ʻana me ka hoʻoheheʻe ʻana.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 1.00-1.05 g/cm3

He aha ka nylon?ʻO ka thermoplastic ʻenehana

He ʻāpana i hana ʻia mai ka nylon

Nylon(aka polyamide (PA)) he thermoplastic i hoʻohana pinepine ʻia no nā noi ʻenekinia, ma muli o kāna mau waiwai mechanical maikaʻi, ikaika hopena maikaʻi a me ke kiʻekiʻe kemika a me ke kūpaʻa abrasion.Hiki ke komo i ka wai a me ka makū.

ʻO Nylon 6 a me ka nylon 66 nā māka i hoʻohana pinepine ʻia i ka mīkini CNC.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 1.14 g/cm3

He aha ka polycarbonate?ʻO ka thermoplastic me ka ikaika hopena

ʻO kahi ʻāpana i hana ʻia mai ka polycarbonate

ʻO ka polycarbonate kahi thermoplastic me ka paʻakikī kiʻekiʻe, ka machinability maikaʻi a me ka ikaika hopena maikaʻi loa (ʻoi aku ka maikaʻi ma mua o ABS).He akaka, akā hiki ke hoʻoluʻu i nā kala like ʻole.Hana kēia mau mea i mea kūpono no ka nui o nā noi, e komo pū ana me nā mea fluidic a i ʻole nā aniani automotive.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 1.20-1.22 g/cm3

He aha ka POM (Delrin)?ʻO ka plastik CNC machinable loa

He ʻāpana i hana ʻia mai POM (Delrin)

ʻIke ʻia ʻo POM e ka inoa kalepa ʻo Delrin, a he thermoplastic ʻenehana me ka machinability kiʻekiʻe loa ma waena o nā plastics.

ʻO POM (Delrin) ka koho maikaʻi loa i ka wā e hana ai ʻo CNC machining i nā ʻāpana plastik e koi ana i ka pololei kiʻekiʻe, ka ʻoʻoleʻa kiʻekiʻe, ka haʻahaʻa haʻahaʻa, ka paʻa o ka dimensional maikaʻi loa i nā wela kiʻekiʻe a me ka haʻahaʻa haʻahaʻa o ka wai.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 1.40-1.42 g/cm3

He aha ka PTFE (Teflon)?ʻO ka thermoplastic wela wela loa

ʻO kahi ʻāpana i hana ʻia mai ka PTFE

PTFE, ʻike nui ʻia ʻo Teflon, he thermoplastic ʻenekinia me ke kūpaʻa kemika maikaʻi a me ka wela a me ka coefficient haʻahaʻa o ka friction o kekahi paʻa i ʻike ʻia.ʻO ia kekahi o nā plastik liʻiliʻi hiki ke kū i nā mahana hana ma luna o 200 degere Celsius a he insulator uila koʻikoʻi.Loaʻa iā ia nā waiwai mechanical maʻemaʻe a hoʻohana pinepine ʻia ma ke ʻano he lining a hoʻokomo paha i loko o kahi hui.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 2.2 g/cm3

He aha ka HDPE?ʻO ka thermoplastic waho & paipu

ʻO kahi ʻāpana i hana ʻia mai ka HDPE

Polyethylene kiʻekiʻe (HDPE)He thermoplastic me ka lakio ikaika-a-kaumaha kiʻekiʻe, ka ikaika hopena kiʻekiʻe a me ke kūpaʻa maikaʻi i ka wā.He māmā ka HDPE a kūpono no ka hoʻohana ʻana i waho a me ka paipu.E like me ABS, hoʻohana pinepine ia e hana i nā prototypes ma mua o ka Injection Molding.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 0.93-0.97 g/cm3

He aha ka PEEK?ʻO ka plastic e pani ai i ka metala

ʻO kahi ʻāpana i hana ʻia mai PEEK

PEEKhe thermoplastic hana kiʻekiʻe me nā waiwai mechanical maikaʻi loa, kūpaʻa wela ma luna o kahi ākea ākea o nā wela a me ke kūpaʻa maikaʻi loa i ka hapa nui o nā kemika.

Hoʻohana pinepine ʻia ʻo PEEK e pani i nā ʻāpana metala ma muli o kona kiʻekiʻe ikaika-a-kaumaha ratio.Loaʻa nā māka lāʻau lapaʻau, e kūpono ana ka PEEK no nā noi biomedical.

Nā hiʻohiʻona waiwai:

❖ Māmā maʻamau: 1.32 g/cm3

Nīnau pinepine

❖ He aha nā mea maikaʻi o ka mīkini CNC me nā metala?

He kūpono nā metala no ka hana ʻana i nā noi e koi ana i ka ikaika kiʻekiʻe, ka paʻakikī a me / a i ʻole ke kūpaʻa hilinaʻi i nā wela wela.

Ke kumu o ka ʻatikala:https://www.hubs.com/knowledge-hub/?topic=CNC+machining

Ka manawa hoʻouna: Mei-10-2023